New benchmark offers opportunities for functional packaging improvement and cost savings.

New benchmark offers opportunities for functional packaging improvement and cost savings.

Europe’s leading paper-based packaging manufacturer Smurfit Kappa has developed the first packaging benchmark for beer and beverage can trays, which can be used by manufacturers to make functional improvements and reduce their packaging costs.

The Smurfit Kappa packaging benchmark includes key market sector requirements, gives performance rankings for current solutions, highlights the most cost effective and functional options, and proposes innovative solutions to fulfil market requirements at reduced cost or to add value at minimum extra cost.

The study focused on packaging performance within the retail supply chain for 0.3-0.5L can trays. It included logistic efficiency, mechanical performance and appearance on shelf evaluations. It aimed to identify packaging options which would hold pack contents together, improve containability, prevent buckling, reduce transit damage, enhance on-shelf presentation and reduce shelf filling time.

Tim Oakley, National Account Manager at Smurfit Kappa said: “Our company has been making beer and beverage can trays for decades. We know this market segment inside out – and fully understand its functional requirements. We were therefore in a perfect position to ‘measure’ performance in this area.

“Retailers often complain about stock ‘shrinkage’ because of damaged cans, that torn trays affect shelf image and that there is a loss of time filling beers and beverage shelves. This is all due to poorly designed beer and beverage trays.

“Through our work – and due to our extensive knowledge of other packaging sectors – we have not only been able to identify functional best practice and outline innovative solutions, but also identify various opportunities for cost savings. We can now share this information to brand, marketing and product design managers at beer and beverage manufacturers throughout the UK.”

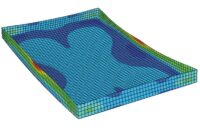

To conduct the study Smurfit Kappa’s European Development Centre developed new ‘retail functionality performance measurement’ test tools. These were designed to quantify and compare tray stability and containability, to find minimum specifications for retail performance and to identify the lowest design and production costs. Each benchmark was conducted by a European collaboration of Smurfit Kappa’s technical country co-ordinators and specialists.

Currently available benchmarks from Smurfit Kappa include packaging for the wines and spirits market, whilst under development are plastic bottle detergents and milk/juice/water Tetra Pak benchmarks. The new beer and beverage can tray benchmark is a ‘cross market solution’ and can also be used for trays with other cylindrical self-carrying primary packs, such as food cans, glass jars and bottles.

For further information on Smurfit Kappa retail ready packaging benchmarks, please contact Tim Oakley on 0870 8503877 or email enquiries@smurfitkappa.co.uk www.smurfitkappa.co.uk

Comments are closed.