Packaging giant partners to develop more responsibly produced point of sale to meet ambitious sustainability targets

As consumer spending power and consciousness grows, the impact on brands and businesses to fuel more sustainable commitments is widespread. With shoppers often favouring retailers that they trust to reduce the negative environmental impacts across the supply chain – the race is on to eradicate unnecessary plastic.

As consumer spending power and consciousness grows, the impact on brands and businesses to fuel more sustainable commitments is widespread. With shoppers often favouring retailers that they trust to reduce the negative environmental impacts across the supply chain – the race is on to eradicate unnecessary plastic.

ASDA continues to focus on the removal of unnecessary plastic in stores, targeting a 15% reduction on own brand plastic by 2021. As part of the work towards this ambitious target DS Smith were approached to develop more sustainable in-store solutions. As one of the UK’s most well-known supermarket brands ASDA asked DS Smith to support its efforts in innovation and challenge the necessity of certain point-of-sale displays.

As part of this work the teams from both companies came together to re-evaluate the use of plastic mop trays, a point of sale display add-on previously considered a store operations ‘must-have’. The trays are used at the bottom of free-standing displays, protecting them from liquids during the store cleaning process and should spillages occur. However, with advancements in the way stores are maintained and cleaned, by carrying out a light risk assessment, and challenging the status quo, DS Smith found that the removal of the trays does not in fact risk the safety or quality of the point of sale. This has now led to the removal of plastic mop trays saving approximately 8 tonnes of plastic a year and reducing the carbon footprint for each POS unit by up to 15%.

The visual element of POS displays that is often not seen by shoppers, has also been challenged by the two teams. Premium corrugated materials are often used to ensure the integrity and strength of stock holding displays, but the process of making white corrugated board often involves bleaching in the manufacturing stages. To eliminate the emissions incurred during the bleaching process, ASDA and DS Smith teamed up to produce several prototypes that led to the design of an equally robust solution; the new design contains more recycled content and a reduced CO2 footprint while still retaining visual appeal for consumers.

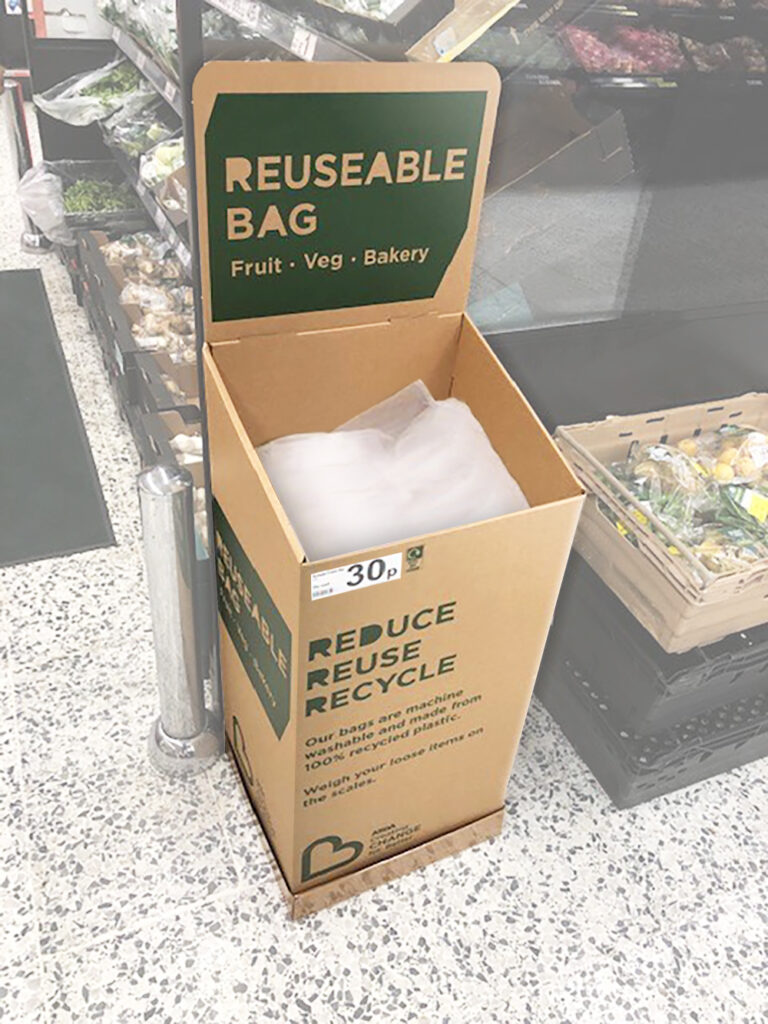

To build on this exciting work, ASDA and DS Smith are also eagerly anticipating the launch of their next joint development – a brand new fully recyclable POS unit launching in August. The new unit will be used to promote ASDA’s machine washable fruit & vegetables and reusable bakery bags. It has been designed using an innovative technology that allows maximum longevity; remaining robust and secure for several months and also featuring a liquid-proof non-plastic base to protect the board from grease and fluids.

Angus Jones at DS Smith commented: “We’re thrilled to be able to work with ASDA on plastic replacement and practical solutions and that lower the overall carbon footprint of its stores. This is a great example of the benefits that customers can reap when they make subtle but impactful changes in areas of their business.”

“I’m incredibly proud of the DS Smith team, who through continuous testing and learning, have made further strides to encourage greater sustainability within the retail landscape, while showing they can still address and solve common marketing challenges in tandem.”

Lisa Walker at ASDA commented: “We are constantly working to re-evaluate where we can reduce the quantity of non-recyclable packaging in our entire supply chain, whilst continuing to meet resource efficiency and practicality requirements for our in-store colleagues.

Reducing plastic and our impact on the environment is very important to our customers and this project with DS Smith is testament to our commitment to reducing our carbon footprint and removing unnecessary plastic from the planet.”

Comments are closed.