DS Smith Packaging is a leading supplier of Retail Ready Packaging (RRP). RRP has become part of the daily UK shopping experience across a huge range of groceries, with shoppers increasingly interacting with it every time they buy.

DS Smith Packaging is a leading supplier of Retail Ready Packaging (RRP). RRP has become part of the daily UK shopping experience across a huge range of groceries, with shoppers increasingly interacting with it every time they buy.

Today’s marketers see opportunity to integrate RRP design into the mix, to generate sales, in store, at the point of purchase. DS Smith Packaging is collaborating with them more and more to help achieve the results they need, whether in brand positioning, visual disruption in the category or making promotions succeed.

The company’s RRP solutions enhance suppliers’ and retailers’ performance from factory floor to retail store, delivering lower supply chain costs, product availability and efficient replenishment.

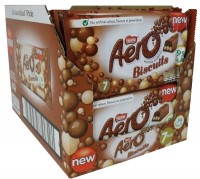

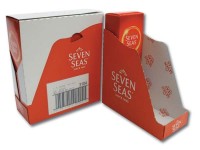

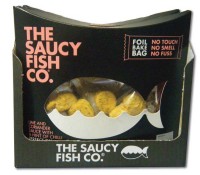

Clients for recent major RRP projects include Cadbury, Seven Seas and Seabrooks Crisps, and award-winning packs for GlaxoSmithKline, Nestle and Mimosa Market Ltd.

Terry Morgan, Market Development Director for DS Smith Packaging, spoke to The Grocery Trader.

GT – Terry, what does your role involve as Market Development Director for DS Smith Packaging? How much of your work specifically involves Retail Ready Packaging?

I’m responsible for marketing, development and design activities across our UK operations. The majority of our business is in FMCG, so helping customers achieve results with RRP is fundamental to our thinking.

GT – How are you set up to service the needs of the brand owners and retailers?

Our technical and design specialists support customers and their project teams, in packing, distribution, marketing or in store operations. We use organised methods to access innovation and a systematic design approach, built into our PackRight business tools.

GT – This interview is all about Retail Ready Packaging, but first, a few questions about DS Smith as a whole. When was DS Smith founded? Who owns DS Smith now? Do you operate in any other countries besides the UK?

DS Smith is a FTSE 250 company, with market capitalisation of around £1.5 billion. Current operations generate sales of around £1.8 billion. The Group focuses on corrugated packaging, especially for consumer goods, is market leader in the UK and has strong positions in France, Italy and Eastern Europe.

DS Smith is a FTSE 250 company, with market capitalisation of around £1.5 billion. Current operations generate sales of around £1.8 billion. The Group focuses on corrugated packaging, especially for consumer goods, is market leader in the UK and has strong positions in France, Italy and Eastern Europe.

GT – You recently bought some of SCA’s packaging operations. Can you tell us about that?

The DS Smith Group recently reached agreement to acquire the corrugated packaging businesses of SCA Packaging, and completion is anticipated in the second quarter of 2012.

GT – What does this acquisition bring to your business?

The enlarged, combined group will be able to provide packaging to major brand holders across Europe, including Germany, the Nordic region, Benelux and the East.

GT – When did you start making Retail Ready Packaging and merchandising units?

We were there from the very beginning! RRP was available before demand accelerated in the last five or six years, and our oldest patent in this area is 16 years old. DS Smith Replen has recently introduced a variety of reusable equipment to meet demand for merchandising units – for example a platform of 800 x 600 mm, which can operate as a pallet or a wheeled dolly.

GT – How big a business now are in-store RRP merchandising units in the UK? How big a part of your UK business are they?

Though smaller scale than on shelf RRP, sales of merchandising units and associated display packaging are growing. DS Smith Replen and DS Smith Multigraphics, our POP and POS business, are substantial operations in their own right.

GT – How do merchandising units fit into the retailer’s toolbox?

Where sales rates are fast enough, there’s a clear role for units that are wheeled or pushed into store, and used for display in lieu of shelving. Off shelf and gondola end promotion is growing too, as the dynamic needs of seasonal campaigns and brand promotion accelerate, and as convenience operators become more sophisticated in accessing impulse sales.

GT – What makes an RRP solution successful in store?

Increasingly, brand marketers recognise how integrating RRP and consumer pack design works for shoppers at the point of purchase. Structure, material and print can help position the brand, or support product launches through visual disruption.

Successful RRP enables shoppers to recognise products, and take them from the shelf easily. In potentially confusing categories, RRP can separate products on shelf, helping shoppers to identify and buy the product or variant they want. This contribution to shopper convenience drives sales directly.

At the same time, it’s imperative that RRP makes in store operations efficient. It has to be easy to identify, easy to open, and of the right size to make replenishment simple, fit the shelf and achieve optimum sales rates. Good availability and range depend on that.

GT – How does the UK compare with the rest of the world in terms of deployment of RRP units in store?

RRP penetration is greater in the UK than elsewhere, although plenty is now happening in other parts of Europe and in North America. Outside the UK, RRP has a long history in discounters and much has been done in creative displays for seasonal events. General RRP usage is growing across Europe.

RRP penetration is greater in the UK than elsewhere, although plenty is now happening in other parts of Europe and in North America. Outside the UK, RRP has a long history in discounters and much has been done in creative displays for seasonal events. General RRP usage is growing across Europe.

GT – If you can summarise, how does RRP deliver value in the supply chain?

RRP delivers value from factory floor to retail store – in short, more sales, lower supply chain costs, efficient packing operations and less waste.

GT – What kind of difference can RRP solutions make to retailers and suppliers’ packaging and distribution efficiency?

Pack design, to make best use of the cube on pallets and vehicles, often takes out cost and carbon. Correct case depth optimises case fill. Strength can be matched to the physical demands of single or double stacking on vehicles.

Best use of space offers such big rewards – sometimes we’ve seen over 50% of delivery journeys eliminated. The same improvements also reduce demand for warehouse space. Some customers eliminate bottlenecks and achieve significant growth, with little or no new distribution cost. That’s a valuable prize!

Detailed design for packing efficiency can also reduce cost and promote growth. Productivity gains of 10 to 15% on existing lines are not uncommon.

For users considering new packing lines, the right combination of RRP design and machinery will literally pay dividends. Good decisions make all the difference to return on investment.

GT – What’s your USP as a RRP provider? Why come to DS Smith for an RRP solution? What sets you apart from other manufacturers in this area?

Our customers value innovation, in the full sense of making ideas happen. Making the best use of RRP needs insight and refusal to accept second best.

Our customers value innovation, in the full sense of making ideas happen. Making the best use of RRP needs insight and refusal to accept second best.

Practical scope and scale is vital too. Customers can access a comprehensive range of print and structural options for the right solution. RRP for large multipacks and tiny units for top end beauty products are very different!

Finally, RRP design for sales, cost reduction or lower carbon is at the centre of what we do. Using our PackRight tools, we work systematically with customers to quantify likely results, and achieve them quickly. Many customers use our Impact and Innovation Centre, with its tactile and visual supply chain and in store environments, to stimulate action.

GT – What different types of in-store RRP do you supply, and what kinds of products would you use them for?

We supply RRP into all relevant food and non-food grocery categories, for almost every type of consumer pack, from sachets and pouches to cartons, tubs, bottles or whatever.

GT – What recent innovations have you launched?

DS Smith Packaging’s innovation is driven by anticipation of trends and by customer need. Recent examples include TiltMaster, which displays product on a backwards tilt, so it does not fall over. The patented ShelfMaster range offers clean opening and high quality appearance, but can be packed on equipment intended for traditional cases. Innovation in high-speed automation of two-piece packaging is accelerating. Transit hoods can be removed instantly, leaving only a printed tray to contain the product for on shelf display.

During 2011, DS Smith Packaging’s R-Flute® products made large-scale inroads in RRP, providing supply chain savings and a better print surface than alternatives. We emphasise innovation, to use no more packaging material than necessary. Best use of materials and resources is fundamental to our business and our customers’ thinking.

GT – What are the different elements/components in an in-store merchandising unit?

Essential components comprise a base, which may be reusable or single trip, and the product, usually in its consumer pack or with the consumer pack in RRP. Some products, for example some bottles, only require separating pads and a wrap, to form a unit that can be packed, shipped and displayed in store. Important developments in automated packing are taking place in this area.

More often, display sleeves, headers or even shelving are included, to meet promotional or supply chain needs. For easy deployment of the units, many are now delivered to store, pre-packed for immediate use. A transit hood protects the unit in distribution and is quickly removed on arrival.

GT – How easy is it to track down your RRP units at the back of store? Are they bar coded, RF tagged and so on?

Clear print on several sides of the pack to identify the product, preferably with a picture or diagram, is vital. When store staff find product easily, shelves are replenished, waste prevented and good availability achieved. We often see this at first hand, when our people are invited to work in store to check RRP designs and performance.

Clear print on several sides of the pack to identify the product, preferably with a picture or diagram, is vital. When store staff find product easily, shelves are replenished, waste prevented and good availability achieved. We often see this at first hand, when our people are invited to work in store to check RRP designs and performance.

Colour coding sometimes helps, to distinguish broad product types. Bar coding maintains identity through the chain, especially in distribution centres.

GT – Presumably for most clients you don’t start from scratch every time you design an RRP solution, you have a bank of retail-ready packaging solutions that you adapt?

Broad families of RRP suit different product types, but adaptation can be vital.

For example, the same product may be packed in different boxes, because packing lines vary, but they can be engineered to appear consistent when opened and on shelf.

In store, the right structural detail retains consumer packs safely during replenishment, whilst making it as easy as possible for shoppers to see the product. Small variations, such as a curved tray lip to match a brand logo profile, can add enormously to impact, with no supply chain complication.

GT – What is the minimum order quantity for one of your RRP solutions?

There’s no universal answer to that, but most demands can be satisfied by different types of production unit across our network.

GT – At what stage do you get involved in the planning for promotions that use your packaging solutions? How far ahead do you work? Can you turn around last-minute solutions?

With some customers, we participate very actively in planning and concept work. Partnership can yield excellent results, as complete promotional packages are brought together and both parties innovate for brands they know. Well-scheduled campaigns reduce cost and are generally more effective.

Nonetheless, we’ve also run projects where packed product was delivered in under a week from initial discussion of concept.

GT – Are there peak times of year for demands for in-store RRP solutions?

Many RRP solutions are used continuously, as the normal packaging format. However, seasonal occasions such as Christmas, Easter and back to school create major peaks, especially for displays and promotions. With corrugated packaging, we can respond to them very quickly.

GT – Do you work direct with clients, or with their design agencies, or both?

Our main contacts are necessarily with customers who buy packaging. We also work hard to understand what retailers need and spend a lot of time in store, getting to grips with the practical issues. However, contact with agencies is becoming much more frequent, as marketers recognise how RRP can drive sales.

Our main contacts are necessarily with customers who buy packaging. We also work hard to understand what retailers need and spend a lot of time in store, getting to grips with the practical issues. However, contact with agencies is becoming much more frequent, as marketers recognise how RRP can drive sales.

GT – Can you talk us through your various clients and your work for them? Do you publish client case studies?

DS Smith Packaging supplies leading multinational and national brand holders across the FMCG spectrum, and numerous own brand producers too. Our network always handles many projects for design and innovation concurrently.

In collaboration with our customers, we regularly publish case studies, such as those featured on the next page of this edition!

GT – What industry standards do you work to?

ECR UK’s guidelines to Retail Ready Packaging remain very useful. Although originally published as long ago as 2007, they still offer a sensible view of RRP functionality.

GT – How ‘green’ are your RRP solutions? Can they be recycled?

All of our RRP can be recycled. Over 80% of corrugated packaging is recycled in the UK, and a still higher proportion of grocery RRP. DS Smith Recycling is the UK’s leading operator, with a highly effective infrastructure.

GT – How important is recycling to DS Smith as a group?

Recycling, with all the sustainability benefits it brings, is central to the Group’s activities. DS Smith makes paper, converts it into high performance packaging, collects the used packaging and starts the process again.

GT – Have you won any design awards for your RRP solutions?

Yes, often! We’re always very pleased to receive awards on behalf of our customers and their brands. We have won the Retail Ready Packaging category in the UK Packaging Awards for the last two years. Last year we were delighted that we’d produced all three shortlisted entries. We have been successful with entries to Starpack and Worldstar too, as well as in specialist print events.

GT – Where do you see retail ready packaging going from here as an element in the marketing mix?

We see it building on where it is now – completely integrated into the mix, as a tool deployed for results at the point of purchase.

GT – What effect has the difficult economic climate had on demand for RRP solutions?

Demand for FMCG packaging has proved robust. RRP is a valuable business tool in tough times as well as good. Demand for new projects remains strong as marketers adapt for success in changing circumstances.

Demand for FMCG packaging has proved robust. RRP is a valuable business tool in tough times as well as good. Demand for new projects remains strong as marketers adapt for success in changing circumstances.

GT – Finally, where do you see your RRP business going?

In the UK, we see further RRP penetration in some categories, and continuous design refinement. Packs that don’t perform will be eradicated. More customers will invest in products and packing lines for optimum performance.

We will play our full part in enabling marketers to implement RRP, to support brand positioning, category navigation, visual disruption and product launches. Consistency in colour, look and feel, will be high on the agenda.

Very strong recycling infrastructure, and technologies to make best use of materials, will continue to underpin everything we do.

DS Smith Packaging

Tel: 0845 260 7080

email: ideas@dssp.com

Comments are closed.