Traceability broadly means the ability to track any food, feed, food-producing animal or substance that will be used for consumption, through all stages of production, processing and distribution.

Traceability broadly means the ability to track any food, feed, food-producing animal or substance that will be used for consumption, through all stages of production, processing and distribution.

The traceability of grocery products in the retail supply chain has been a source of debate within the food industry ever since the EU introduced the General Food Law in 2005. This statute outlines the legal requirement for food business operators to ensure firstly, that all food products are safe for consumption, secondly, that food can be followed from source to the processing operation and then onto the organisations it is initially supplied to – so called “one up and one down” traceability and thirdly, that withdrawals can be targeted effectively and accurate public information made readily available.

Whilst most food businesses do comply with this requirement, there is a need for greater awareness within the industry of the competitive advantage benefits that wider traceability across the supply chain can bring, says Pascal Durdu, the person responsible for Innovation and New Solutions at Zetes. “Traceability offers a lot more than food safety management. It allows the manufacturer to better fulfill a retailer’s information requirements, supports providing greater levels of information to consumers and helps to promote differentiating attributes such as organic or Fairtrade,” he says. “Not to mention the potential to improve supply chain performance.”

As Europe’s leading provider of data capture/automatic identification solutions for goods and people, Zetes has over 20 years’ experience in this field. The company’s approach is to carefully analyse customer needs, identify the required level of traceability necessary and then integrate a wide range of data capture technologies including voice, image capture, barcodes, RFID, print and apply, plus smart cards. By combining the optimum range of technologies for its grocery clients, Zetes can ensure full product traceability at each stage within the supply chain, improved quality assurance and compliance with industry standards, as well as increased productivity and operational accuracy in the warehouse. And this is borne out by research. In a recent study conducted by Zetes amongst its customers, 89% said the solutions they had implemented significantly improved traceability, accuracy and productivity, amongst other benefits. Specifically, traceability provided information which can be used to improve supply chain processes, decrease costs and improve quality. It also helped to improve inventory management, reducing wastage from poor shelf life management, reducing shrinkage and controlling out of stock situations. Current Zetes customers in the food and beverage sector include retailers like Morrisons, Co-op, Henderson (Spar), Waitrose, Aldi and Lidl; distribution specialists such as Keystone and Ocado, CEVA Logistics and Tradeteam; manufacturers including Premier Foods, Seachill, Carlsberg, Coca Cola, PepsiCo, Cadbury and Nestlé.

Within grocery circles the traceability debate tends to focus on food, but Pascal Durdu is emphatic that data capture and identification issues are equally applicable to the beverage sector. “We see no difference in the need for supply chain traceability between food and drink. Both involve many fresh products or a requirement for authenticity, and the customers commissioning traceability solutions are the same – retailers and producers. And for any item which is perishable, accurate data capture of expiry dates is critical to ensuring reaction times to stock deliveries are short and that stock levels are kept to a minimum.”

Within grocery circles the traceability debate tends to focus on food, but Pascal Durdu is emphatic that data capture and identification issues are equally applicable to the beverage sector. “We see no difference in the need for supply chain traceability between food and drink. Both involve many fresh products or a requirement for authenticity, and the customers commissioning traceability solutions are the same – retailers and producers. And for any item which is perishable, accurate data capture of expiry dates is critical to ensuring reaction times to stock deliveries are short and that stock levels are kept to a minimum.”

Pascal Durdu believes traceability is beginning to rank higher on the food industry agenda for two key reasons. Consumers are increasingly interested in knowing where their groceries, and the raw ingredients used, come from, and secondly, because producers and retailers alike have begun to appreciate that offering this level of transparency gives them a competitive advantage. There are also the operational benefits to consider – better visibility and traceability across the entire supply chain makes it easier and less costly to implement targeted recalls, which often involve large quantities of products and can very quickly damage a company’s reputation.

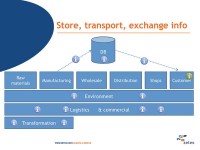

“Traceability is an issue affecting the whole supply chain,” Pascal points out. “Especially for product recalls – under the EU regulations, companies need to know where they receive goods from and ship to, and be able to trace them back to source.” In a typical supply chain with multiple stakeholders, all participants need to be aligned with the right technology and level of traceability, adequate temperature monitoring in the warehouse and so on to ensure the right products are being shipped in the right condition, at the right time, to the right place, for the best possible price. This is what Zetes describes as operating a ‘demand driven supply chain’. “For example,” says Pascal, “we have one customer, Seachill, who is using image capture technology Visidot, to record details of fresh fish shipments supplied to Tesco. The system validates not only that shipments are correct as quickly and accurately as possible when they leave the warehouse, but ensures that Seachill can maintain records with visual proof that all previous shipments are as commissioned.”

The key question for customers considering how to address traceability, is what do you track? – the goods, or the packaging? It depends on the operation of course, but Pascal is clear about how to assess this. “You need an agreement among supply chain partners to share and store information, tracking and tracing it at the appropriate level. Everyone in the supply chain needs to be in agreement over how much data should be captured and shared.” Pascal continues, “With a small batch of product, knowing the date of delivery is probably enough. Encoding further information might not always be necessary because in many cases, expiry data and so on is not recorded on the barcode. What is tracked most typically is the movement of pallets when they enter the warehouse and problems occur when goods are broken down into smaller units than pallets. Ultimately, the level of monitoring undertaken depends on the type of goods and the organisation’s risk profile – it is very feasible to track goods at both carton or batch level, and monitor delivery dates.”

The key question for customers considering how to address traceability, is what do you track? – the goods, or the packaging? It depends on the operation of course, but Pascal is clear about how to assess this. “You need an agreement among supply chain partners to share and store information, tracking and tracing it at the appropriate level. Everyone in the supply chain needs to be in agreement over how much data should be captured and shared.” Pascal continues, “With a small batch of product, knowing the date of delivery is probably enough. Encoding further information might not always be necessary because in many cases, expiry data and so on is not recorded on the barcode. What is tracked most typically is the movement of pallets when they enter the warehouse and problems occur when goods are broken down into smaller units than pallets. Ultimately, the level of monitoring undertaken depends on the type of goods and the organisation’s risk profile – it is very feasible to track goods at both carton or batch level, and monitor delivery dates.”

Understanding the technology

The linear bar code is by far the best-known traceability technology in the food and drink industry. But looking ahead, barcodes are now moving to data matrices capable of holding far more detailed information, such as the 2D barcodes already widely used in pharmacy applications. It is simply a matter of time before 2D barcodes become widespread within the grocery sector.

The full list of product identification solutions now available from Zetes includes voice technology for large-scale picking, 2D cameras for rapid reading of barcodes on cartons, input systems with expiry data on printed barcodes, mobile terminals and, finally, RFID, still a largely unexplored territory within the grocery trade.

All these technologies are being implemented within the sector, says Pascal Durdu. “At the start of a project, we sit down with the customer and identify the best method for the item to be tracked: should they trace cartons or the plastics crates holding cartons? Do they already use RFID tags?” Everything Zetes does contributes to the product’s overall traceability, Pascal points out. “Our solutions are predominantly sold as a means of improving efficiency and productivity, but importantly, they can also be used for traceability.” He cites voice picking as an example of where this is the case. Voice picking is often adopted because it enables faster, more accurate picking through hands-free working. It also improves traceability, because we know in which container every picked item has been placed and this information could be valuable when orders are split later in the supply chain process.

“We now have very high level discussions about traceability issues with customers and are increasingly acting as strategic partners, helping them to develop road maps for the future. Our ultimate goal is to support customers in creating a demand driven supply chain, where data is captured at the right time across each stage of the journey from producer to customer. We can receive goods from suppliers and track them with 2D images of pallets, plus improve picking efficiency and traceability. Every solution we develop needs to form an integrated part of a larger data chain which can be enabled at a future point to show who moved which goods, from which location, when this occurred and where they went. Then, in addition to having an audit trail, going forward, customers will be able to more accurately forecast demand and ensure they minimise out of stock situations, especially when promotions are involved.”

As yet, Pascal concedes there still is no automatic way to notify consumers in the event of a recall, so external media and notices in store are still required. “However, the speed with which problems can be identified is very much improved. We have the technology and integration capability to cover the whole chain and select the right technology for each situation because we’re not tied to any particular vendors or products. We also offer real-time activity management solutions and can adapt the technology to the type of goods, the distribution operation and the business model.”

As yet, Pascal concedes there still is no automatic way to notify consumers in the event of a recall, so external media and notices in store are still required. “However, the speed with which problems can be identified is very much improved. We have the technology and integration capability to cover the whole chain and select the right technology for each situation because we’re not tied to any particular vendors or products. We also offer real-time activity management solutions and can adapt the technology to the type of goods, the distribution operation and the business model.”

Different types of food and drink operations have different information requirements regarding traceability, and Zetes provides the framework to enable them. In a given supply chain involving a variety of partners, there are typically several different systems to be integrated. “Our technology integrates successfully with a customer’s existing ERP and WMS systems. We also have connector products enabling different products and applications to exchange information with a minimum of software development required.”

For the majority of clients, Zetes advises on high-level strategy, but for others they implement a given solution. There are now Zetes solutions in every UK retail operation, used for everything from printing and labeling, to scanning, to proof of delivery, to picking and put-away and which are used to improve either traceability or efficiency or both. “We supply both big and medium companies using EDI, and increasingly, smaller, speciality food producers who retain information on smart cards.” To serve this sector, Zetes recently launched a new EPoD (electronic proof of delivery) system, which uses a combination of smart cards and RFID to track and trace product information. Providing a very low cost of ownership solution, a smart card containing consignment data is used by the producer’s driver to provide detailed information, which is transferred to the customer upon arrival at the warehouse, after being read using a wall-mounted terminal.

“We launched our first smart card product in February,” says Pascal, “and are planning more. They are ideal for small suppliers dealing with big retailers, where investment in EDI simply isn’t practical.”

“We launched our first smart card product in February,” says Pascal, “and are planning more. They are ideal for small suppliers dealing with big retailers, where investment in EDI simply isn’t practical.”

Where the law stands

The EU General Food Directive announced in 2002 and applied in 2005, aims to protect the health of the EU citizen, checking where a product comes from and goes to, and puts measures in place to enforce this. There are also ISO standards for international movements of goods outside the EU in place since 2007, and in Europe new standards for suppliers and retailers.

This generic legislative approach is set to remain the same, with modifications for specific products and different retail environments.

In Pascal’s eyes, most UK retailers and producers are complying properly, and making product information public by printing it on their packaging. “There are still problems with recalls, and traceability measures vary depending on the degree of risk – it’s mostly being done, but its effectiveness depends on the remedial work afterwards.”

One growing application for traceability is in the fight against food fraud, such as vodka being diluted with industrial methanol or poultry unfit for human consumption being repackaged and sold to unsuspecting consumers. Although these acts resulted in criminal prosecutions, the vast majority of cases are simply where non-authentic foods are marketed as being the ‘real thing’. “As the desire to eat authentic speciality foods rises, small scale producers and farmers are increasingly interested in protecting the well being of their industry. This may not pose a specific health risk, but damages the reputation of the foods in question because premium products have been substituted or adulterated with cheaper products. You may have eaten ‘fake’ buffalo mozzarella which is made from cow’s milk,” he adds.

“The Norwegian government understands the value of this, and is supporting its food industry to become the leaders in Europe with advanced traceability systems that really do span from farm to fork. For instance, one local lamb producer has implemented a system that allows the consumer to trace its organic meat products right down to the field in which the animal has grazed on organic grass.

At the supermarket, joints are labeled with a 2D barcode and shoppers can use their mobile phones to trace the journey each joint has made to the supermarket shelf. If there ever was an example of true farm to fork traceability that’s it, the only information missing in the chain is how it is ultimately cooked and consumed.”

Although a lot of hype exists about ‘Farm To Fork’ traceability, Pascal thinks this is an achievable goal, based on a short supply chain and Track and Trace procedures. “It is feasible to achieve this, but first you need to simplify things and minimise the steps involved, with the right data captured in the right format and at the right time. It’s especially possible for retailers buying a given product from a single manufacturer.”

The big question is, what does it cost a company to achieve this? It needn’t be excessive, Pascal believes. “In many cases, the information might already be there in another application, such as a WMS.” He maintains that “streamlining procedures will lower costs, as will using the right technology for the product and the supply chain, simplifying things for everyone. “The final cost also depends on the way a business runs its supply chain operation, the value of goods, their lifespan and numerous other factors.

The big question is, what does it cost a company to achieve this? It needn’t be excessive, Pascal believes. “In many cases, the information might already be there in another application, such as a WMS.” He maintains that “streamlining procedures will lower costs, as will using the right technology for the product and the supply chain, simplifying things for everyone. “The final cost also depends on the way a business runs its supply chain operation, the value of goods, their lifespan and numerous other factors.

Traceability isn’t just about obeying regulations, but offering visibility and maintaining quality to create competitive advantage.”

Another expression becoming more widely used within the food industry is ‘smart supply chains.’ Again Pascal Durdu is keen to demystify this concept. “Smart supply chains come about through the individual parts of the supply chain gathering information in a smarter way, with greater visibility and efficiency. A good example is a system designed to reduce waste in the fresh food supply chain caused by products reaching their best before date before being sold, or where their shelf-life and condition is impacted because of events occuring during storage and transportation. “It comes down to good store management – the right products, the right picking, the right stock allocation for that shop, understanding the shelf life, having good temperature management during storage and transportation and knowing what needs to be shipped first – good stock management and a deep analysis of what must be tracked are prerequisites.”

To achieve this, Zetes can introduce ‘smartpoints’ which monitor a variety of environmental conditions and provide an alarm if boundary levels are exceeded, such as cold store temperatures rising too high. These devices can also wirelessly transmit information to calculate updated shelf-lifes, by connecting automatically to the network upon reaching a final destination and ensuring a greater level of accountability by allowing identification of when and where the out of spec condition occurred. As all companies involved in the grocery supply chain try to minimise their environmental impact and act responsibly, minimising waste becomes more than simply a cost management issue.

“It’s still down to the customer – whether the producer, shipper or retailer,” says Pascal, “to track and trace specific information, but we can help them analyse the information they need to capture and work out how best to transmit it to the end user elsewhere in the chain.”

In the event of a product recall, he says having a smart supply chain and farm to fork traceability means less risk and less work – “you can confine the geographic area of a recall to where you know the product is, in which retailer and even which DC, instead of looking everywhere. This massively reduces the damage to a brand’s reputation, and also the costs associated with the issue.”

Won’t this mean changing the way companies operate? “It might force them to change how they work, and simplify and add more steps, but it will have a positive impact overall,” Pascal argues. If it costs money, how likely are companies’ managements to make this change in the present economic climate? “The economic climate isn’t an issue – companies need to be more efficient now anyway to survive. People are increasingly focusing on efficiency and reduced shrinkage as part of their commitment to sustainability – improved traceability means you can better manage stock, reduce wastage and authenticate raw materials.”

The way forward

Traceability in the UK food and beverage industry still has a long way to go, Pascal believes. In his experience, although most of the UK’s largest food and drink businesses have traceability technology in place, they are not yet using it at an adequate level. The next few years will see a step by step evolution in the supply chain, based on increased efficiencies rather than purely following regulations. “To get full traceability in place for the next five years, people need to identify what information they need, how to capture, store and share it, and define the steps required to achieve it, reviewing partnerships with suppliers, logistics partners and retailers. Once this is in place, we can develop a traceability roadmap and find the right combination of technology to deploy it.”

To find out more about Zetes, call 01344 290063, email info@uk.zetes.com or visit our website at www.zetes.com

Comments are closed.