Packaging specialist Expo Industries Group’s new 120,000 sq. ft purpose built has come on line to serve a growing European customer base.

The state of the art, eco-building is committed to sustainable and environmentally friendly manufacturing and provides Expo’s UK and European customers with a full print packaging service that includes print, die cutting, window patching, laminating, gluing and heat seal capabilities. There are also CTP reprographics and plate-making services on site.

Derby-based Expo Industries UK is a member of the Expo Industrial Group, and UK Managing Director Jonathan Harris-Lowe said the new factory in Sri Lanka provides a sustainable endorsement to the ‘concepts to delivery’ service offered by the Group.

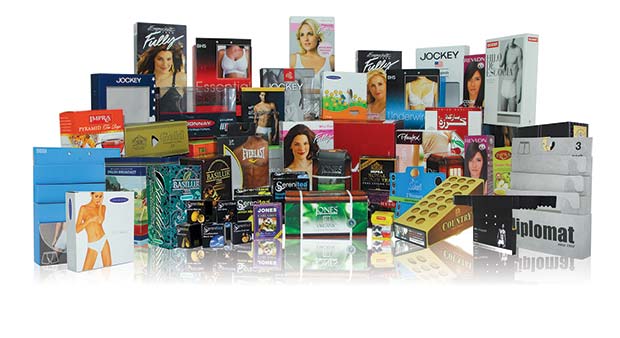

The UK operation provides the Group’s marketing, customer service, studio, design and warehousing services. The Group is now in its 21st year of producing merchandising solutions in the apparel and food processing sectors. Products include hangtags, PFL, woven and adhesive labels, printed folding box board cartons, rigid boxes, PET boxes, polyprop cascades, plastic hooks, polybags (both food and non-food grade) and decorative metal boxes.

“As a major packaging supplier in the UK we need to be able to produce solutions in an environment that meets contemporary expectations and that’s why the Group has invested so heavily in the factory,” says Jonathan.

UK customers include apparel retailers, multiple chains and leading food and supermarket brands.

“We have built a strong reputation globally as well as in the UK; it’s one that’s built on research, investment and an ability to continually be at the forefront of sector developments. We are leaders in carton packaging, using top quality design, materials and printing techniques, coupled with some of the industry’s fastest turnaround times.

“The reputation for excellence and skills we have built up means the company continuously strives to reduce the environmental impact of being part of a global operation.

“This starts in our factory and can be measured throughout our production and supply chain process. For example, through the sustainable sourcing of all its materials and using FSC and PEFC accredited suppliers and the continuous development of packaging design that reduces the amount of packaging required and wastage.

“A major difference between Expo Industrial Group and its competitors is that the group owns its production sites and can therefore control quality, costs and delivery. That means we can influence and implement change at source,” adds Jonathan.

Expo Industries UK

Tel: 01332 292269

Comments are closed.