The food industry is undergoing constant change. Food manufacturers want to respond flexibly to shifts in the market and changing consumer demand, and to be prepared for these movements. As a result, filling companies and co-packers need the right technical equipment to enable them to provide what their customers want today, while being prepared for what they will want tomorrow. At the same time, if they want to survive long-term in an intensely competitive environment, manufacturers need to find a response to the steadily rising margin pressure. Food Option filling machines from SIG Combibloc offer a convenient response to this challenge in the food business.

Food Option filling machines are new filling machines based on the standard SIG Combibloc filling technology, including only minor technical adjustments prior to machine delivery to enable operators to fill a whole host of additional food products. If a filling machine comes with the Food Option, the quantity of chunky product ingredients can be up to 10 per cent; the size of the particulates can be up to 6 mm, and fibres can be 1 x 15 mm in size; viscosity can potentially be up to 3,500 mPas. This means Food Option filling machines make it possible to fill an unrivalled spectrum of food products aseptically – quickly and with no need for major additional investment. The flexibility of the filling machine technology is also the key to products that allow higher margins.

Right now, the issue of margins is preoccupying the food industry more keenly than ever. Particularly in light of this, aseptic Food Option filling machines from SIG Combibloc may be of interest for any food manufacturer who wants to expand the existing product range by adding more profitable products, without investing in a high-end solution for filling food products such as ready-meals or chunky soups and sauces – regardless of whether it is a beverage producer looking to enter the food business, or an established food manufacturer planning an investment to add further products to the portfolio.

Frank Ludwig, Global Product Manager Food at SIG Combibloc: “SIG Combibloc has more than 35 years’ experience and solid know-how in filling long-life foods and beverages in carton packs. Over the years, we’ve expanded the filling and packaging options we offer ‘bit by bit’, in the truest sense of the words. Today, our ultra-modern food-filling machines can aseptically fill products containing particulates up to 25 millimetres in size – individual fibres can even be as long as 40 millimetres. Products can have up to 50 per cent particulate content. But not every manufacturer who is active in the food business, or looking to enter it, takes full advantage of the possibilities offered by these food-filling machines, which are designed for the ‘crème de la crème’ of liquid food products. However, a whole host of food products can be filled with ease using the leaner Food Option filling machines, which are based on the proven and less complex standard aseptic filling technology from SIG Combibloc”.

Exceptional variety and flexibility

Any food manufacturer opting to aseptically fill products in carton packs will find the solution in the Food Option filling machines from SIG Combibloc, offering an unparalleled level of variety and flexibility. Because alongside classic beverages -whether from the dairy sector or NCSD – with Food Option filling machines from SIG Combibloc, even pasty and high-viscosity food products and products with a specific particulate content can be filled aseptically in carton packs.

An example: With a Food Option filling machine from SIG Combibloc, a manufacturer who originally specialised in producing and filling juices and juice products now has the option of packaging more than just his usual product portfolio in long-life carton packs. He also has the technical requirement to expand his product range, using the same filling machine, by adding products from the food segment, and thereby achieving higher margins. It is not just viscous and pasty products such as Tomato Frito (tomato sauce with oil) that can be filled easily using the new system – tomato passata (tomato purée) and creamy pasta sauces containing herbs or pieces of onion and vegetables are also viable possibilities.

Entering the food business

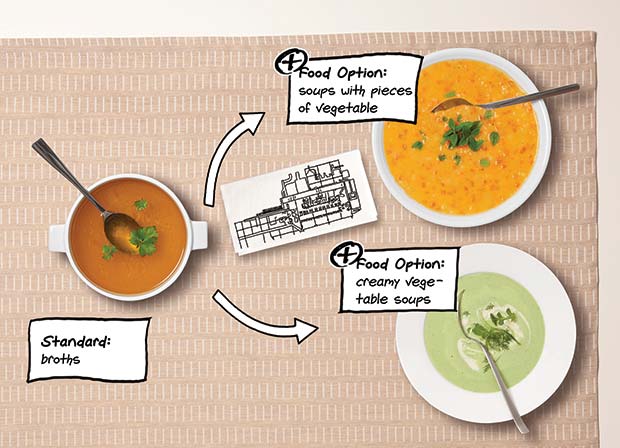

Globally, this diversity is unrivalled. And it can be easily carried over to other product segments such as soups, which can also be filled on Food Option filling machines. As well as filling products such as beverages and bouillons on one and the same filling machine, the Food Option machines can fill more complex, and therefore usually higher-margin products such as veloutés or mouliné soups in carton packs.

In the dairy products sector too, food manufacturers can tap into entirely new business segments. Because it is not just milk and milk-mix beverages that can be filled using the aseptic Food Option filling machines – the more viscous dessert sauces, puddings and custard are possible, as well.

Food manufacturers who are already using the aseptic system in the juice or dairy segment and want to expand their portfolio by adding unusual new products, or who are planning to enter the food business, will be ideally positioned with a Food Option filling machine, enabling them also to fill soups, sauces and desserts containing small particulates and fibres, or very viscous products.

Broadening the possibilities

Similarly, food manufacturers who are already filling food products such as tomato passata, creme soups or dessert sauces in aseptic carton packs, and are thinking about investing in a new, further filling machine for filling food products, can substantially broaden their product spectrum with the Food Option machine from SIG Combibloc.

Frank Ludwig: “With the new Food Option filling machines, we’ve carried over our expertise in aseptic food filling technology, with its unrivalled product variety and flexibility, to standard filling machines. And we’ve done it in a very straightforward way, without bringing additional complexity into the whole system. The customer only pays for what he actually uses. So we’re enabling our customers to tap into completely new, high-margin product segments – and to do so with a very manageable level of investment”.

SIG Combibloc

Comments are closed.