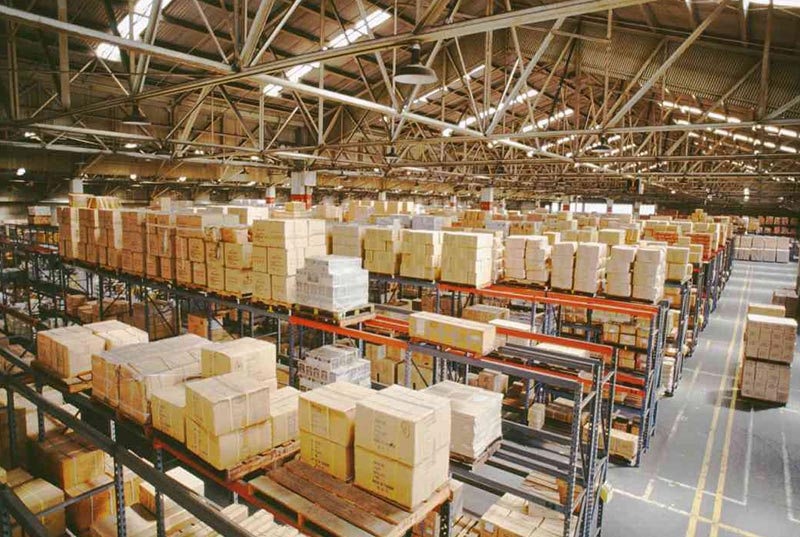

We’re all looking for new ways to save energy, save money and boost productivity within our working environment. One of the main factors we should aim to reduce when we’re trying to save money is downtime caused by machine/vehicle failure, injury and crime. Downtime costs us dearly in 2 ways: it forces us to cease work and production while also forcing us to spend on costly repairs to fix whatever has gone wrong, in short it is one of the most expensive problems warehouses face. There is no way to completely eliminate the risk of downtime but we can dramatically reduce it by implementing new technologies, working methods and maintenance schedules so we can catch potential problems before they escalate.

The measures you take to reduce the risk of downtime and increase overall productivity will depend on the nature of your business; here are 5 common methods to get you started:

1. Stick To A Maintenance Plan

Warehouses are typically reliant on machinery and vehicles which mean huge costs can be incurred in the event of a breakdown. By implementing a regular maintenance plan you can catch any problems early on and they will generally require cheaper, simpler fixes that can be performed within work hours, meaning your warehouse won’t have to shut down operations and you save money long term. Having a professional assess your machinery and vehicles every 6 months also increases general efficiency by making sure your machinery is in top working order.

By singing up for a maintenance package you have the peace of mind that comes from knowing an expert is keeping an eye on your resources and you are protected by a 24 hour call out services.

2. Utilise New Technology

Innovative new technology is always being developed to increase standards and productivity within working environments. There is an initial cost involved for investment in new systems but they can save you money in the future.

Modern warehouse technology is designed with energy efficiency in mind. Energy efficient systems have the dual benefit of cutting your monthly bills and lowering your carbon emissions so you can help meet green standards. Investing in insulated, sliding and bi-fold doors, roller shutters, automated technology, low energy bulbs, insulation and thermostats can all cut your bills and boost staff comfort, productivity and morale. New technology works better and works faster which has a positive knock on effect for the rest of your business.

3. Assess Health And Safety Standards

Keeping staff safe on premises is top priority for all employers. Working with vehicles and machinery always carries a certain amount of risk but your job is to keep it to a minimum, the best way to do this is by undergoing a risk assessment in order to see where health and safety practices might be lacking.

The point of a risk assessment is to determine hazards and think through solutions to ensure staff are safe and won’t need to take time off work to cope with an injury. There are 5 simple steps to undertaking a risk assessment:

• Identifying hazards

• Identifying who is most likely to be harmed and how

• Evaluating risks and finding precautionary measures

• Recording findings and implementing them

• Reviewing assessments and updating where necessary

There’s no need to wrap staff in cotton wool, in most cases the risks will be obvious and the best defence against them is common sense.

4. Streamline Operations

Evaluate how work is completed within your warehouse and identify any areas where time may be wasted or improvements could be made.

Make sure work is completed methodically in a standardized order so nothing slips through the cracks and employees know the process and what they should be doing every step of the way. Make sure your premises is kept clean and free of superfluous items that get in the way and slow down operations so you are able to utilise your entire warehouse space. Consider implementing automated technology to perform certain tasks to reduce the amount of time processes take and give some thought to new computing and technology options that can help you improve accuracy.

5. Upgrade Security

We all want to avoid security breaches. By investing in security doors and grills, access control, CCTV, alarm systems and even security guards you can protect your premises from crime and vandalism. Your premises is likely to be filled with valuable materials that are attractive to potential criminals, visible deterrents like alarms and CCTV let them know someone is watching and protects your property when you aren’t there.

Follow these steps to help keep your premises protected, well maintained and fully functional. By keeping on top of your downtime risk factors you can greatly reduce your chances of suffering and your business will go from strength to strength.

This post was written by Emma Smith on behalf of Enerco High Speed Doors, providers of second to none maintenance services and exceptional, innovative technologies that promote energy efficiency, productivity and security in all types of commercial environment. They utilise the latest knowledge to keep their solutions on the cutting-edge.

Enerco High Speed Doors link to http://www.enercohighspeeddoors.co.uk/

Comments are closed.