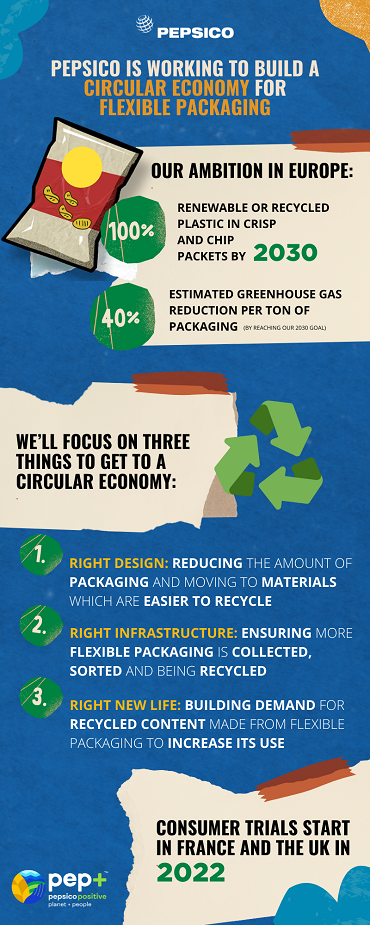

- PepsiCo Europe, which owns UK brands including Walkers crisps, is today announcing plans to use 100% recycled or renewable content in all crisp and snack packets by 2030 – therefore eliminating the use of virgin fossil-based plastic

- The overall ambition aims to reduce greenhouse gas emissions from crisps and snacks film packaging by up to 40%2

- Walkers crisps will lead the charge in the UK by trialling new packaging with recycled content made from crisp packets, biscuit wrappings, shopping bags and other plastics – on a new Walkers crisps range to be launched later this year

- In addition, all Walkers snacks and crisps, as well as Doritos, will move to packaging designed to make them even easier to recycle, leveraging innovative design technology to create a simpler bag structure

- PepsiCo is working to build a circular economy for flexible packaging in the UK and all European markets through design, infrastructure and giving packaging materials a new life, as part of its wider pep+ (PepsiCo Positive) ambition

- PepsiCo UK is urging the government to speed up its plans to include flexible packaging in household recycling collections, so that the industry can begin recycling flexible plastics at scale.

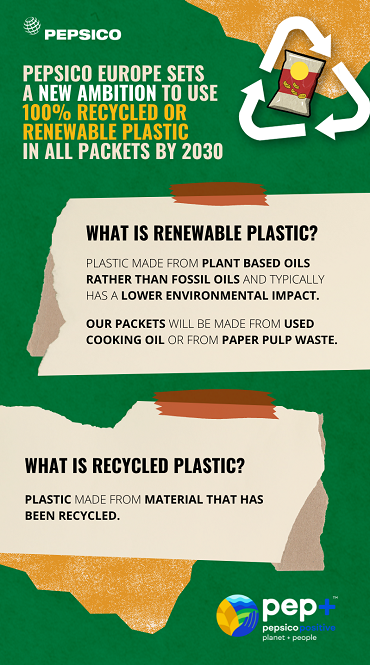

Following the introduction of PepsiCo Positive, the company’s strategic end-to-end transformation plan with sustainability at the centre, PepsiCo Europe today announces that by 2030, it plans to eliminate virgin fossil-based plastic in all its crisp and snack bags. This ambition will apply to UK brands including Walkers, Doritos, Quavers, Wotsits, Snack a Jacks and Pipers, and will be delivered by using 100% recycled or renewable content in its packets.

Following the introduction of PepsiCo Positive, the company’s strategic end-to-end transformation plan with sustainability at the centre, PepsiCo Europe today announces that by 2030, it plans to eliminate virgin fossil-based plastic in all its crisp and snack bags. This ambition will apply to UK brands including Walkers, Doritos, Quavers, Wotsits, Snack a Jacks and Pipers, and will be delivered by using 100% recycled or renewable content in its packets.

New crisp packets, which will include recycled content, are due to be trialled on a new Walkers crisps range in the UK later this year. The recycled content will be derived from previously used plastic, including crisp packets, biscuit wrappers and shopping bags. PepsiCo estimates it may achieve up to 40% greenhouse gas emissions reduction[2] per ton of packaging material by switching to virgin fossil-free material.

Archana Jagannathan, Senior Director Sustainable Packaging PepsiCo Europe and Sustainability Lead UK&I, said: “This announcement and our UK trial are exciting and important moments on our journey towards a truly circular economy for flexible plastics.

“We know change is needed to reduce the amount of virgin fossil-based plastic used in our packaging, which is why we’re working with partners across the value chain to develop effective, scalable solutions to address this.

“At the same time, we need to make it easier for people to recycle their flexible plastics so that we can put this plastic back into the system and to good use. The food industry and retailers have invested to make this possible, with over 3,500 flexible plastic collection points at supermarkets across the country, making it convenient for people to drop off their packaging waste for recycling whilst shopping. Now, we’re urging the government to speed up their plans to introduce kerbside recycling collections, so that we can begin recycling flexible plastics at scale.”

PepsiCo is working in partnership with packaging supplier, AMCOR, to help achieve its packaging ambition across all of its European markets.

Gerald Rebitzer, Sustainability Director at AMCOR, PepsiCo’s flexible packaging partner in Europe, shared: “We are building a future where flexible packaging is part of the circular economy. Together with PepsiCo, we enhanced the material technologies on PepsiCo’s new crisp packet to make it easier to recycle. And we are beginning to integrate renewable and recycled content into PepsiCo’s packaging. To meet the demands of our clients like PepsiCo, we encourage more partners upstream to invest in the supply chains of these new materials.”

The PepsiCo UK snacks packaging plan

To achieve this ambition, PepsiCo UK is on a journey to invest in the right design, support the right infrastructure and help give bags the right new life.

The right design

Over the next 12 months, PepsiCo UK will move all its crisp packets including Walkers and Doritos to materials that make them even easier to recycle, leveraging innovative design technology to create a simpler bag structure. The new bag designs contain greater proportions of recyclable plastics like Polypropylene, commonly referred to as ‘mono-materials’. These meet the design for recycling guidelines developed by the Circular Economy for Flexible Packaging (CEFLEX) which have been agreed by a range of stakeholders active in the flexible packaging value chain. In the UK, the company is working together with OPRL to also modify the labelling on its packaging accordingly to encourage more consumers to recycle.

Walkers in the UK has also been working to reduce any unnecessary packaging. It has reduced some of its multipack outer packaging by up to 30% using innovative technology in its manufacturing facilities. Walkers has also begun to replace plastic secondary large multipack bags with cardboard boxes.

The right infrastructure

Walkers in the UK is committed to investing in infrastructure to give flexible packaging the chance of a second life and in advocating for policy changes that will make that possible. PepsiCo is advocating for the UK government to set ambitious recycling targets for plastic packaging including specifically for flexible film, to accelerate the ban on landfill and to swiftly adopt EPR (Extended Producer Responsibility). As part of this the company is urging the government to speed up its plans to include flexible packaging in household recycling collections, so that the industry can begin recycling flexible plastics at scale.

In the interim, PepsiCo UK is working together with supermarkets to support their 3500+ collection points that make it easy for consumers to recycle any flexible packaging. In 2021, the company, along with four other brand owners founded the Flexible Packaging Fund to support development of recycling infrastructure for materials collected in the supermarkets. Across Europe, PepsiCo is also investing in technology to further scale and improve sorting and recycling of plastics. It is trialling smart packaging on several brands in 2022 in Germany and France as part of the Holy Grail 2.0 Digital Watermarks initiative. PepsiCo is also actively working with partners in the recycling industry such as Borealis and TOMRA too to progress advanced recycling technologies for flexible packaging.

The right new life

Through the ambition, PepsiCo UK will contribute to building demand for recycled material made from flexible packaging. While the goal for PepsiCo is bag-to-bag circularity which is suitable for food packaging, it is clear that recycling of flexible films to produce valuable non-food products can be an important first step towards a circular future.

The announcement today is the latest in the company’s plans to build a world where packaging never becomes waste, one of the focus areas of PepsiCo Positive. The business has already announced its plans to transform its beverage packaging – Pepsi MAX, 7Up Free, Tropicana and all other ready-to-drink beverages in Great Britain will be in bottles (excluding caps and labels) made from 100% recycled plastic by the end of 2022, while bottles (excluding caps and labels) in the entire Naked smoothies range, Lipton Ice Tea (500ml), Tropicana (300ml) and Tropicana Lean are already made from 100% rPET.

1. Ambition applies to all PepsiCo’s snack portfolio in Europe except for Duyvis nuts.

[2]. Based on a Cradle to Grave Lifecycle Assessment provided by Franklin Associates, A Division of ERG, using cut off methodology, a mix of data provided by suppliers and industry, and an estimated 2030 end of life scenario. This Assessment includes carbon storage credits, waste-to-energy electricity production credits, and avoided legacy waste treatment credits.

Comments are closed.