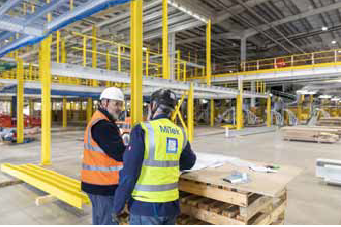

As a UK market leader, MiTek® supplies mezzanine solutions for clients in diverse industries, including grocery retailers, wholesalers and food & beverage manufacturers.

Over the past 40 years, MiTek has delivered more than 20,000 steel platform solutions worldwide for brands including Aldi, Amazon, Asda, Edeka, Gousto, Lidl, M&S, Sainsbury’s and Tesco.

Over the past 40 years, MiTek has delivered more than 20,000 steel platform solutions worldwide for brands including Aldi, Amazon, Asda, Edeka, Gousto, Lidl, M&S, Sainsbury’s and Tesco.

As well as providing additional storage or working space, a mezzanine system can enhance productivity and facilitate growth, often in combination with the introduction of automated handling systems. “Given the labour shortages in the logistics sector,” explains Geoff Green, MiTek’s Sales Director, “many food & beverage manufacturers, distributors and retailers are turning to automation to streamline and accelerate fulfilment. MiTek specialises in bespoke steel structures to support warehouse automation, which can either be installed on top of the structure or suspended from it, keeping the area below free for other warehouse activities. Over the years, we’ve worked in partnership with 9 of the world’s top 10 material handling system suppliers.”

Chilled and frozen areas

Where a mezzanine is required in a chilled or frozen area, the appropriate steel grades will be selected. For example, last year MiTek installed a 7-level mezzanine solution at the Shropshire factory of a major dairy products manufacturer. The customer needed additional space for product storage and installed a fully automated store – served by transfer cars, pallet lifts and conveyors – in a chilled area. In addition to the challenge of working in temperatures of 5ºC or lower, the location lacked access doors, meaning that everything had to enter the site through the roof. To ensure optimum efficiency for the cooling technology, MiTek used self-supporting mesh flooring instead of joists, thereby maximising cold air circulation. Through meticulous planning and a phased programme, the MiTek team successfully installed the 2,500 m2 multi-tier steel structure and ensured seamless integration with the automation.

Brownfield brewery solution

Another recent brownfield project was for the brewery giant, Pilsner Urquell in Czechia. The client wanted to introduce pallet conveyors to its operations but, to keep routes free for forklift traffic, the automation was installed on a five-metre-tall mezzanine structure. MiTek’s experts designed the steelwork to accommodate existing infrastructure at the site and altered the column spacing to enable forklift access. A particular challenge was waterproofing the floor around the main supports, which was vital for handling empty bottles with residual liquid or potential breakages of full bottles. The new installation marks a step-change from traditional forklift-only handling, enabling the brewery to achieve greater efficiency, safety and throughput.

A smaller project was carried out for the British grocery brand, Ocado. Although the total area was just 250 m2, the challenge was to build the structure on top of an existing mezzanine supplied by another contractor. MiTek installed the new mezzanine level – along with staircases and edge protection – in an ambient zone, creating additional space for bagging operations. In addition, decking was added to the existing steel mezzanine structure in both ambient and chilled areas to generate further working space.

Cost savings

“No matter which sector you operate in,” says Geoff Green, “we encourage you to reach out early. Our expert advice on project design can unlock significant savings, while ensuring your mezzanine solution is future-proof, cost-effective, flexible and sustainable.”

Comments are closed.