Equipment manufacturer Starfrost has supplied a bespoke in-line chilling system to Young’s Seafood firm Pinneys of Scotland.

With a state of the art processing facility in Annan, Dumfriesshire, Pinneys supplies Scottish smoked salmon, natural wet fish and premium seafood products including delicatessen items and value added ready meals for M&S. Pinneys is part of Young’s Chilled Division, the UK’s leading producer of seafood for foodservice and retail markets, including all of the major multiples.

Pinneys was looking to increase capacity on a new line of high value steam cooked seafood products, including shell off shrimp, lobster and crab. The company wanted to upgrade from a manual blast chilling process to a fully automated in-line system with energy efficient cooling plant.

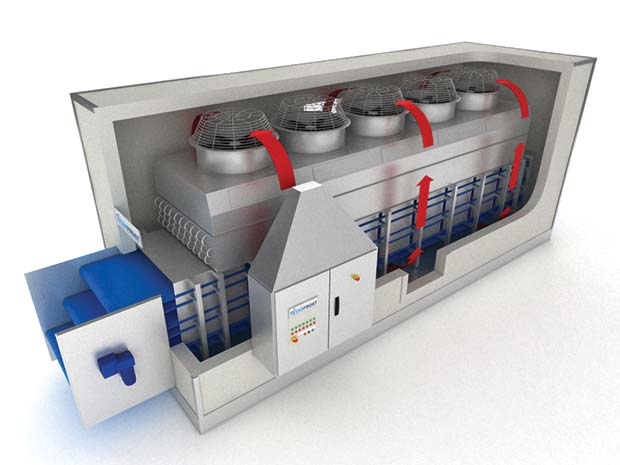

Freezing and chilling equipment specialist Starfrost worked alongside parent company Star Refrigeration to provide a turnkey chilling tunnel and refrigeration plant package for Pinneys. Starfrost custom-designed a Starlite HT (Hybrid Tunnel) chiller for Pinneys following successful product trials on the test unit at its Suffolk manufacturing facility.

With a short lead time of only 12 weeks, the in-line chiller and packaged refrigeration plant were installed at the Pinneys site. Star’s bespoke direct expansion refrigeration plant provides 123kW of cooling to the multi belt Starlite HT.

The Starlite HT links the cooking and packaging line for shrimp, lobster and crab products and has a total chilling capacity of 1,500kg per hour. The new in-line chilling system has enabled Pinneys to boost capacity and increase product quality.

The Pinneys Starlite HT features high velocity impingement air flow and an increased surface area on the air cooler. The increased air velocity allows rapid cooling to minimise weight loss and maximise product quality. With hot product entering the chiller, it was critical to have an increased surface area on the air cooler to allow longer running between defrosts.

The purpose built Starlite HT features three 1m wide product belts within a 3.75m enclosed tunnel. The three close mesh stainless steel product belts are configured to work together on a cascade principle. This creates a flexible and highly compact chilling system, which is fully packaged and mounted on a portable base frame.

The Pinneys Starlite HT features a computerised touch screen HMI PLC control panel and optional CIP (Clean in Place) automated sanitising system. The all stainless steel clean-by-design HT allows easy access to the machine’s interior for cleaning and maintenance.

Starfrost’s Starlite HT (Hybrid Tunnel) is a highly versatile, multi-belt system. It combines the look of a fluidised bed tunnel with the airflow characteristics of a spiral freezer.

The Starlite HT is ideal for upgrading from static blast freezing to continuous in-line IQF processing, or for diversifying or expanding production. It can be adapted to glaze, harden, chill, freeze or thaw a wide range of food products including seafood, meat, poultry, bakery, dairy products, fruit and vegetables.

The Starlite HT offers fast and efficient cooling by using sufficient air volume to rapidly IQF without the need for excessive velocities. Air speed is designed to allow controlled chilling or freezing of light and delicate products. The low maintenance system has a fully accessible stainless steel design for ultimate hygienic operation.

Starfrost’s Starlite HT is designed to offer a cost effective alternative to conventional cryogenic tunnel freezers. The mechanical freezing system offers significantly reduced operating costs compared to a nitrogen tunnel.

Established in 1984, Starfrost has remained a market leader in freezing and chilling technology for over 25 years, working with food manufacturers in more than 50 countries worldwide. Starfrost’s reliable in-line systems are designed to add maximum value, boost production and minimise running costs.

Starfrost

Tel: 01502 562206

Email: sales@starfrost.com

Comments are closed.